Humidity has a way of turning small flooring choices into big problems. In a humid home, the wrong laminate underlayment can trap moisture, soften the feel underfoot, and even contribute to joint stress in floating floors.

We see this most often in North Georgia during long, damp seasons, and in rooms that run wet or warm, such as basements, kitchens, and bathrooms. The good news is that underlayment selection is not guesswork when we follow a clear, moisture-first process.

Start by understanding what underlayment can, and cannot, do

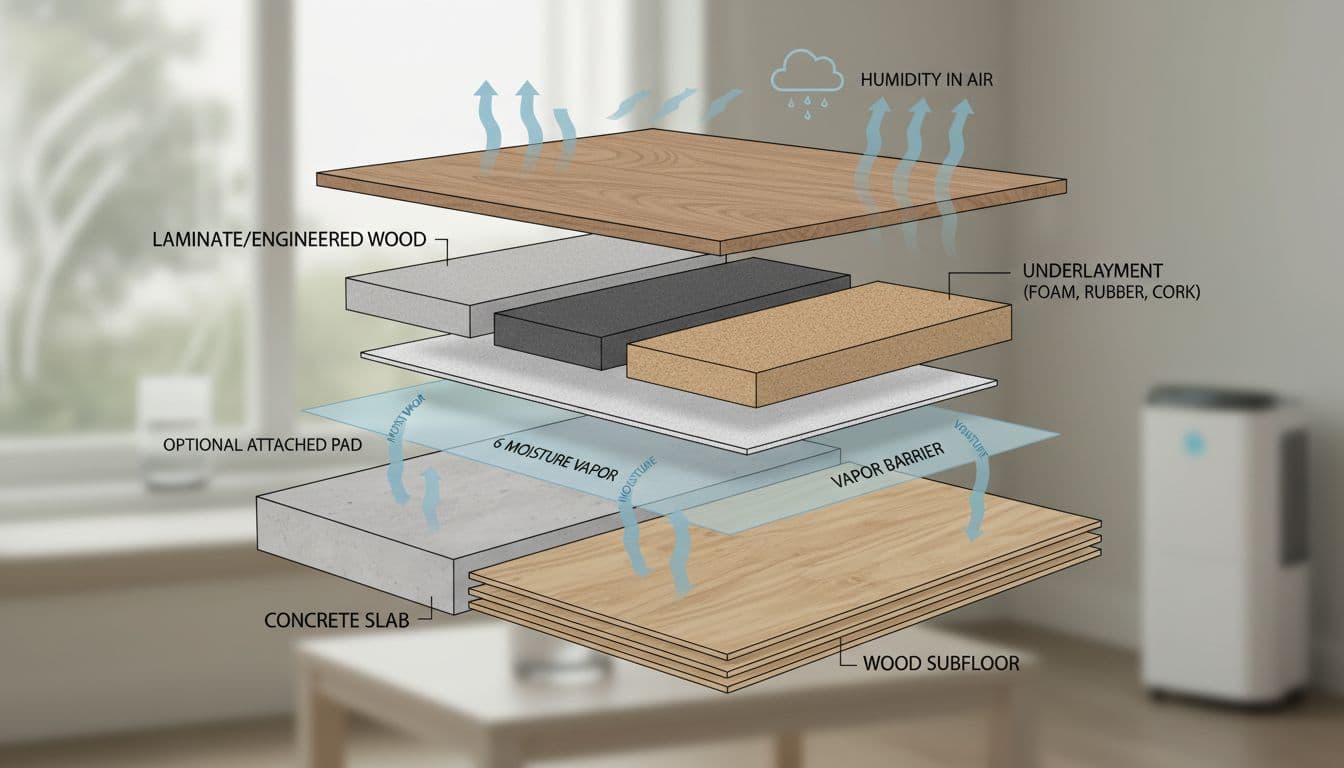

Underlayment is the shock absorber and “buffer layer” in your flooring system. Think of it like a rain jacket liner: it can help manage discomfort (sound and minor feel), but it will not stop a storm if the rest of the system is wrong.

In humid homes, underlayment is mainly chosen for:

- Moisture control (either through a vapor barrier, or by pairing with one correctly)

- Sound reduction (especially in upstairs rooms and condos)

- Support and compression resistance (to protect click-lock joints)

- Minor subfloor smoothing (not leveling)

Underlayment does not fix a wet slab, a leaking appliance line, or an uneven subfloor. If moisture is active, we address the source first.

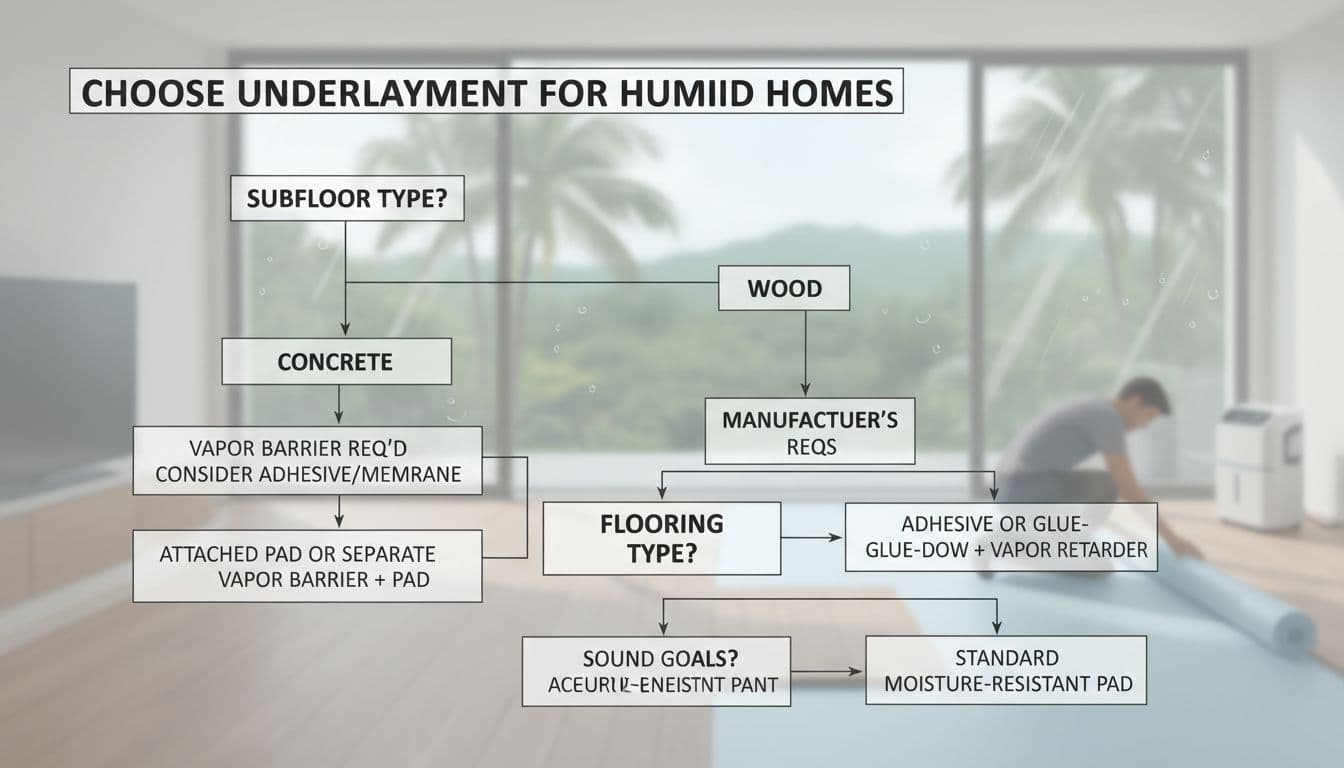

Follow the manufacturer requirements first (warranty depends on it)

Before we pick a product, we read the flooring instructions. Many laminate brands require a specific underlayment type, thickness range, and sometimes a specific vapor barrier method. Some engineered floating floors also have strict limits because soft pads can allow flex, which can stress the locking system over time.

If you want a deeper technical reference on vapor movement and perm ratings, the National Wood Flooring Association underlayment publication (PDF) is a strong starting point. We use these concepts to match the assembly to the site conditions instead of relying on marketing claims.

A practical rule we follow in humid homes is simple: never choose underlayment based on comfort alone. Moisture and structure come first.

Identify your moisture risk: concrete slab vs wood subfloor

Humidity inside the home matters, but what is under the floor matters just as much.

Concrete slab (higher vapor risk)

Concrete can release moisture vapor for years, and humid weather can raise vapor drive. For slab installs, we usually prioritize a true vapor barrier strategy.

In many cases, that means either:

- An underlayment with an integrated vapor barrier, or

- A separate 6-mil polyethylene layer installed correctly, plus the required pad on top (if the floor calls for it)

If you want a clear overview of moisture barrier types and where they fit, this explainer on types of moisture barriers for floors helps homeowners understand the terminology.

Wood subfloor (different risk profile)

With plywood or OSB, we still respect humidity, but the approach is different. A plastic vapor barrier can trap moisture in the wrong situations if the assembly cannot dry. Engineered wood is also sensitive to trapped moisture because it is still real wood.

This is where we rely on the flooring instructions and the room’s conditions. If you are not sure, we treat it like a building envelope decision: we plan where moisture can go, not just how to block it.

Choose the underlayment type that matches humid conditions

Not all pads behave the same under load and moisture. Below is the way we explain it to clients during estimates.

| Underlayment type | Best use in humid homes | What to watch |

|---|---|---|

| Foam (basic) | Low-risk areas over dry wood subfloors when approved by the flooring brand | Often needs a separate vapor barrier on slab, can feel “spongy” if too thick |

| Cork | Good for sound and a firmer feel under engineered floating floors when moisture risk is controlled | Not a vapor barrier by itself, needs correct pairing on slab |

| Rubber | Strong sound control and compression resistance, useful in multi-level homes | Cost, and it still may require a separate vapor barrier depending on slab conditions |

| Combination underlayment with built-in vapor barrier | Common choice for slab installs with laminate underlayment needs | Seams must be taped correctly, thickness must match flooring limits |

For homeowners who want a quick reference on laminate-specific underlay options, the BuildDirect laminate underlay guide outlines common categories and why they are used. We treat those categories as a starting point, then match them to the actual site.

If you are shopping locally, you will also see many “moisture-resistant” products sold for this purpose. A simple way to compare what is available is to look at a broad category page like moisture-resistant underlayment options and then confirm which ones meet your flooring brand’s requirements.

Laminate vs engineered wood: the decision is similar, but not identical

Laminate floating floors are often installed with a dedicated pad system, and many products are designed for that setup. The core concern is keeping vapor from reaching the locking edges and keeping the floor stable.

Engineered wood can be installed in several ways (floating, glue-down, or nail-down). Underlayment choices vary more because the method changes the moisture path and the feel. A floating engineered floor usually needs a firmer, compression-resistant underlayment than a soft foam that might be acceptable for laminate.

We also pay attention to the room. Bathrooms and laundry areas create spikes in humidity that are hard on any wood-based product. If you are planning a remodel, we coordinate flooring decisions with the whole project scope as a bathroom remodeling contractor in alpharetta and Milton, and we often align kitchen flooring plans when clients hire us as a local kitchen remodeling contractor in alpharetta.

Humid-home installation details that matter more than the product

The best product still fails when installation shortcuts creep in. In humid homes, we focus on a few non-negotiables:

Acclimation and HVAC control: We keep indoor conditions stable before and after install. Flooring should not be installed during wild swings.

Seam sealing: Vapor barriers only work when seams are overlapped and taped as required.

Flatness: Underlayment does not level. A floor that flexes will stress joints.

Transitions and expansion space: Floating floors move. Humidity increases movement, so edges need the correct gap.

If you are refinishing existing wood instead of installing floating flooring, moisture control still matters. As a hardwood floor sanding contractor in alpharetta, we see cupping and edge swelling when indoor humidity is ignored during and after refinishing.

When it makes sense to bring in a local pro

If you are on a slab, installing below grade, or mixing new flooring with a remodel, it is worth getting eyes on the full assembly. As a flooring contractor in alpharetta ga, we base the underlayment selection on the subfloor type, room use, and the flooring brand’s written requirements, then we install it to match.

For a free estimate, call us at 470-352-1156. If you show us any existing quote from other contractor we beat it by 5%.

Conclusion

In humid homes, underlayment is not a minor accessory, it is part of the moisture plan. The right laminate underlayment depends on your subfloor, the flooring brand’s rules, and whether you need vapor control, sound control, or both. When we choose the system as a whole, floors feel better, wear better, and stay more stable through seasonal humidity. If you want us to confirm the correct build-up for your home, call 470-352-1156 for a free estimate, and we will review options with clear pricing and a straightforward plan.